I have a friend who is a keyboard aficionado...

...and my addiction with keyboards started because I wanted to make him go crazy. Aparently, using 3D printed components in your keyboard does all sorts of things to its sound profile. I don't mind, though, its all just fun to me.

This chain of projects has been going on over the past few years and may have a new CNC machined iteration coming out in the near future! So, to jump right in, my first keyboard:

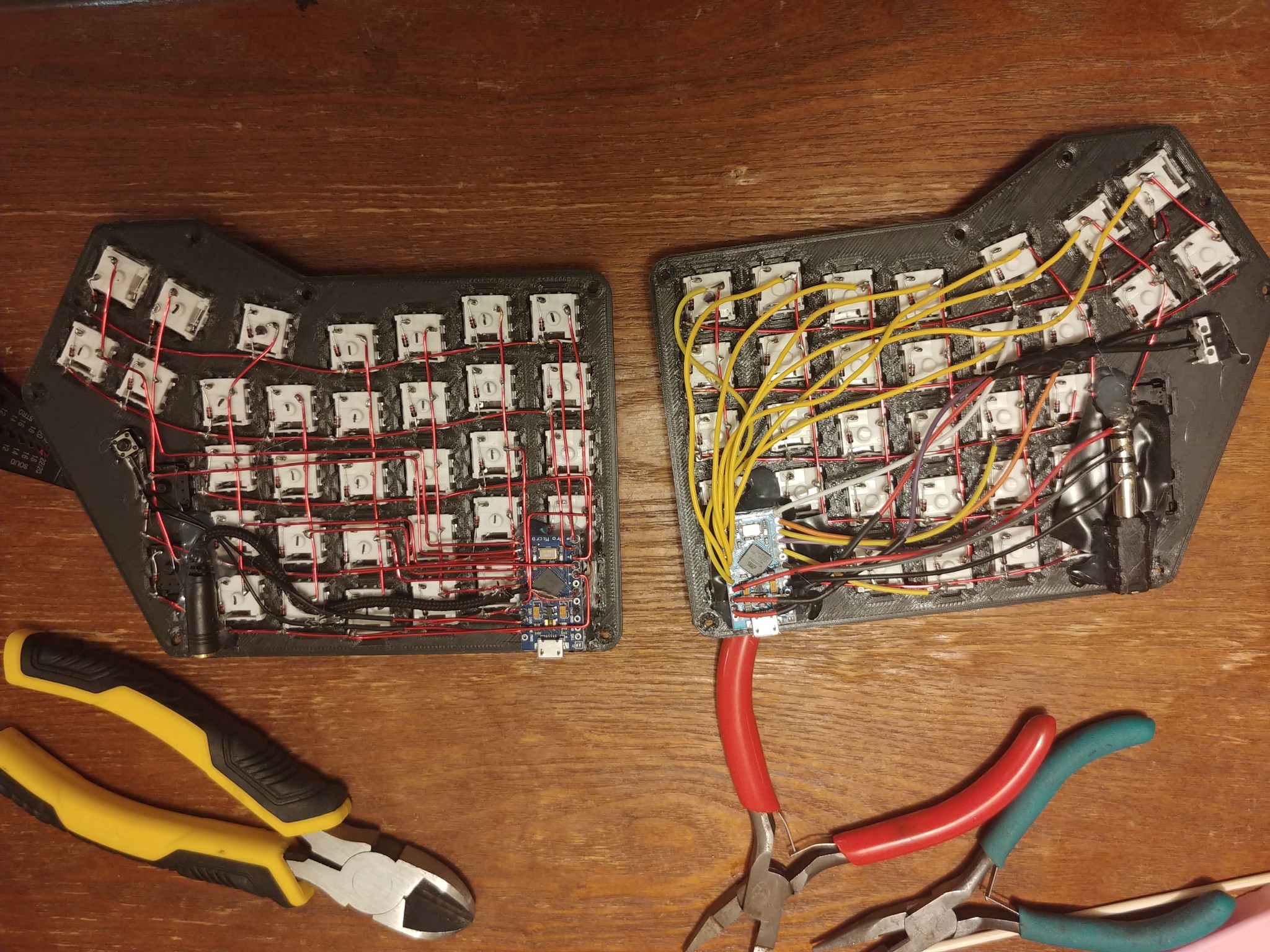

Ortholinear split keyboard with Kailh Green switches for extra click. I was a barbarian back then.

This was a design I found online, so I will keep it brief. This was my introduction to the world of building keyboards and most of the difficulty for me was the volume of solder joints and learning how to build the firmware for the board.

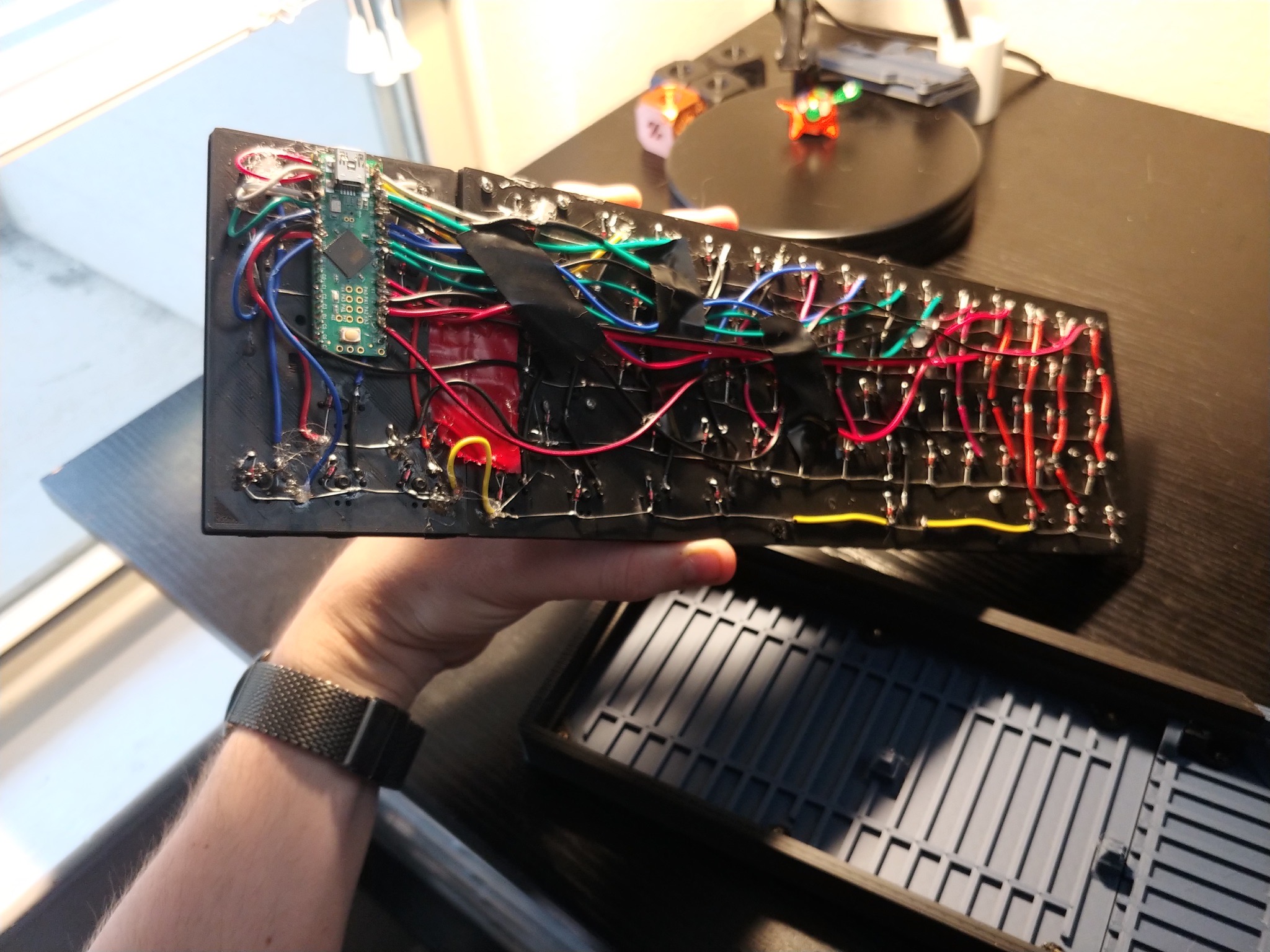

Yes, this entire keyboard was hand soldered! You can see I did the left side first and had it figured out by the time I got to the right.

The unique thing I did in this design was 3D printing everything, even the keycaps. I had just gotten a cheap resin printer online and I jumped at the excuse to use it! I ended up dying a clear resin with a deep transparent blue. After printing, I painted the lettering, cleaned it up, and finished things off with a few layers of clear coat. When I was done, my aficionado friend called me a monster. (“The switches aren’t even lubricated and ...well... just look at it!”)

Keycaps in progress.

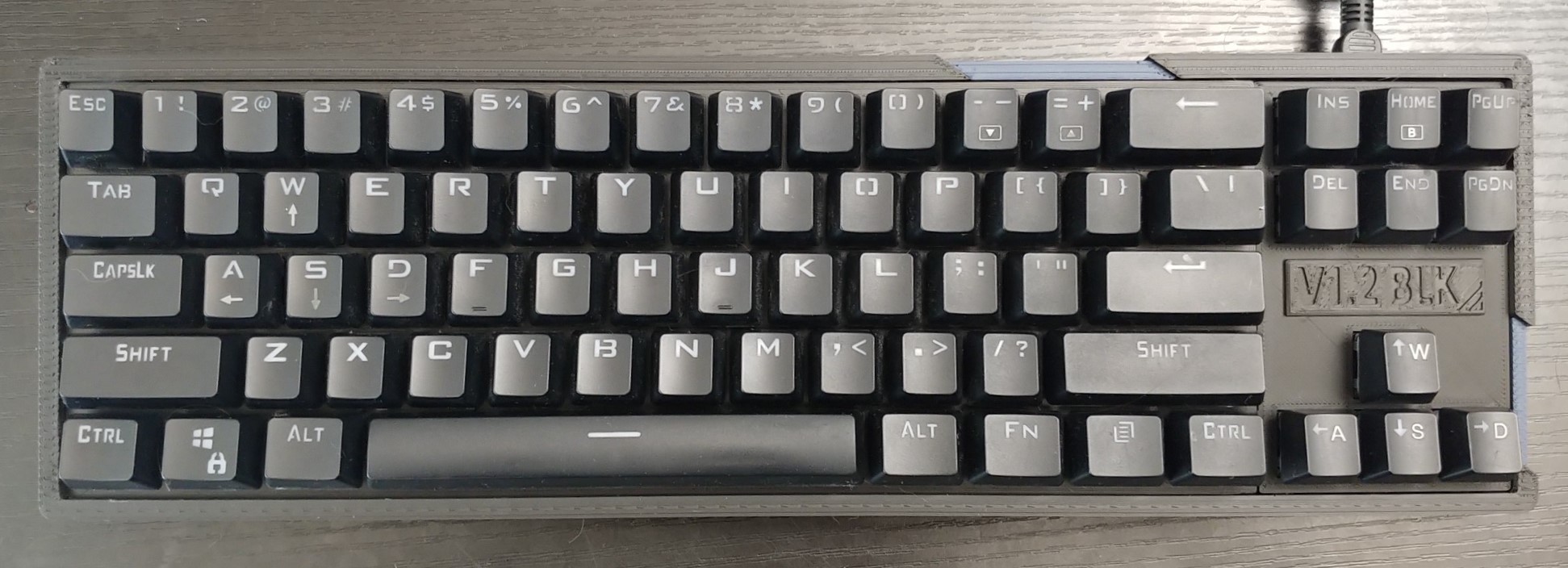

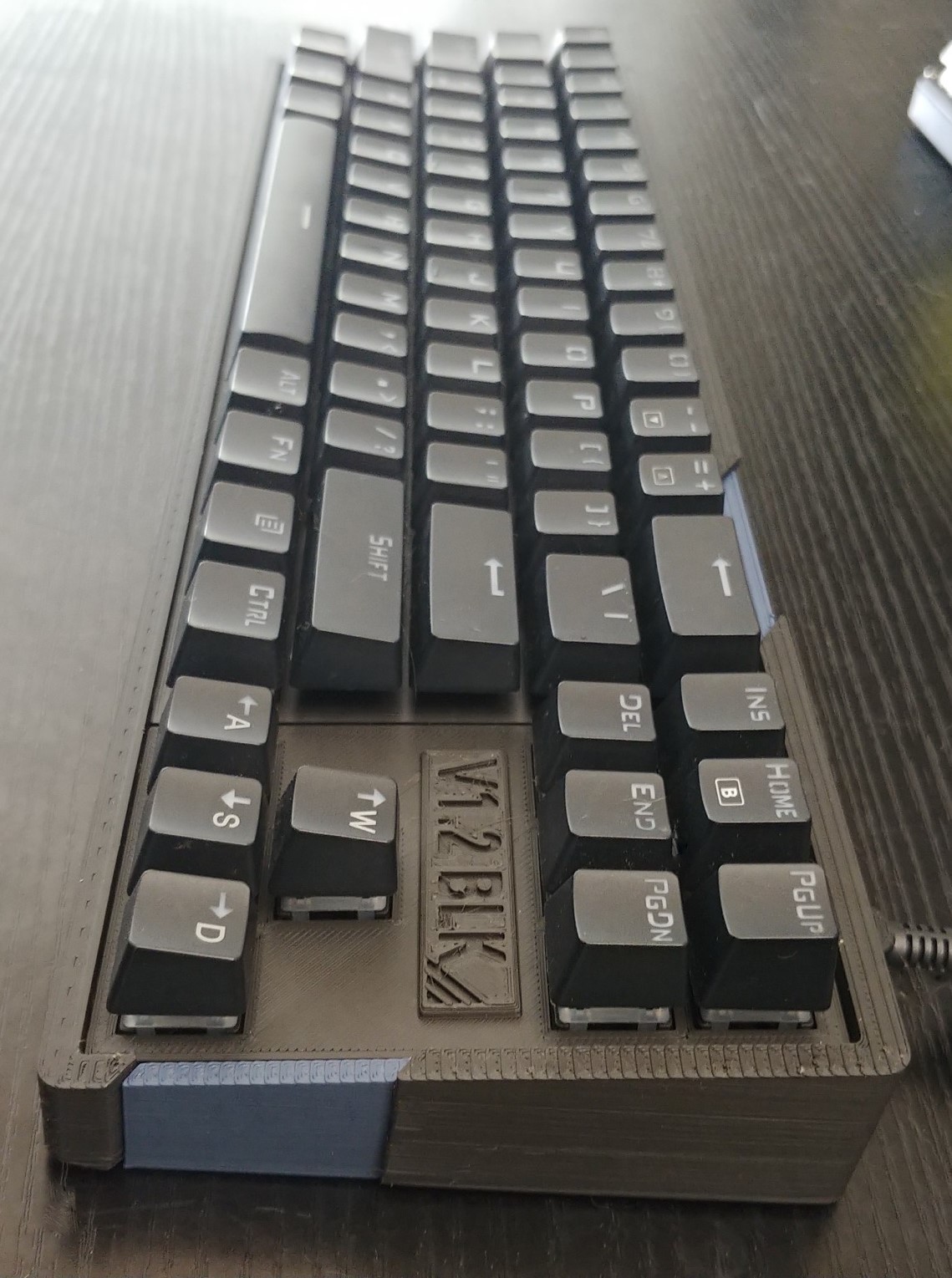

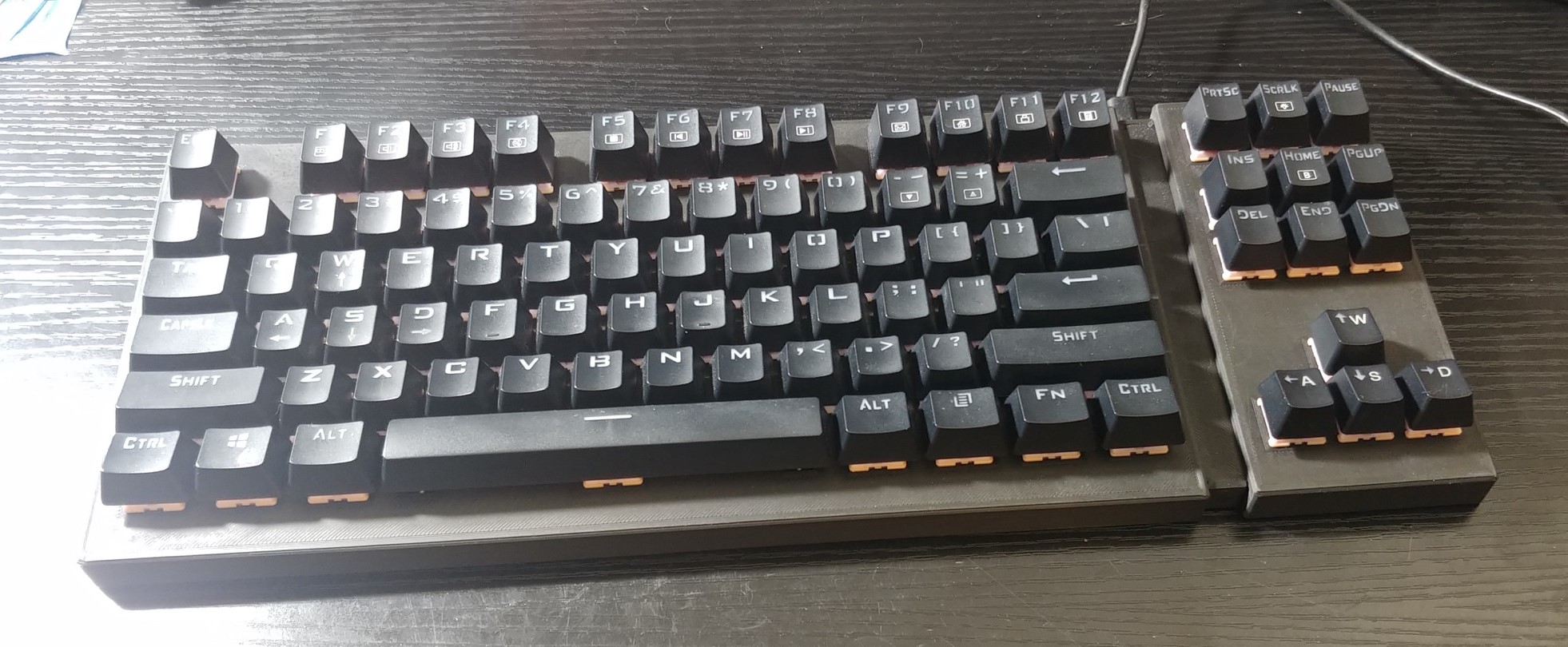

My next board was one that I designed entirely myself. This time I didn’t print the keycaps, but I did have to contend with the limits of my printer’s volume.

If you notice, the top right corner is a separate part from the rest of the keyboard. Printer sizing shenanigans.

Again, my friend wasn’t a fan of this board from an aesthetic or keyboard rigidity standpoint. I couldn’t disagree that cutting the keyboard down the middle makde it less rigid (and 3D printing it for that matter). However, I couldnt’t tell the different between this and “rigid” boards so it still meet the requirements specified by the end user, me. Also, I thought it looked pretty cool. I still think it looks pretty cool.

Finished product.

I didn’t fix the spaghetti wiring on this one either…

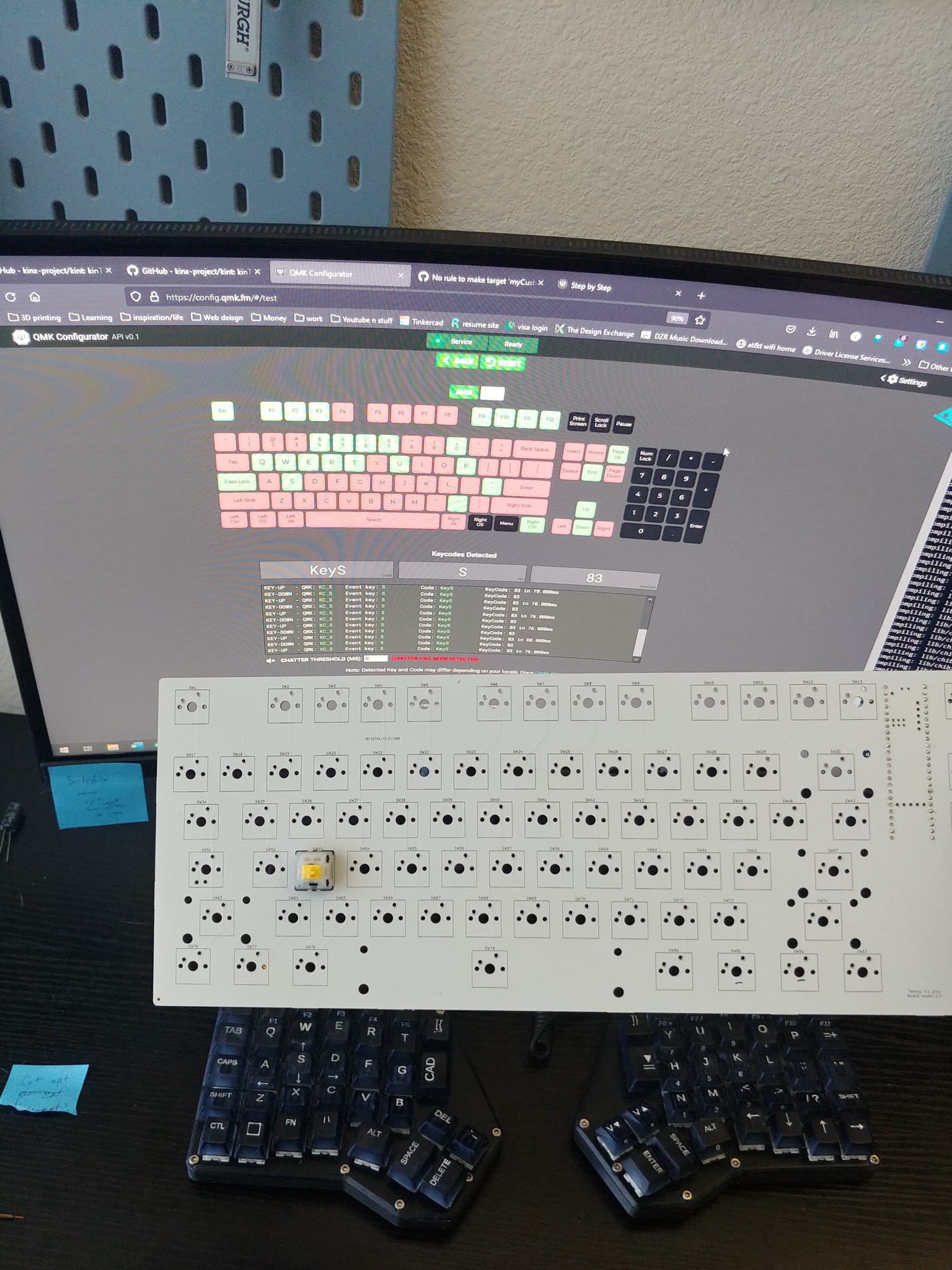

For my most recent board, I wanted to do something about the spaghetti wiring so I learned how to use KiCad and got some proper PCBs made with JLCPCB.

The moment of truth! The wiring worked!

I also updated the design to a simpler case – aesthetically and from a printing complexity standpoint. And apparently my friend was right about the mushy feeling of my last keyboard. I used it as my daily driver at work and it slowly drove me crazy! With a stiff PCB backing the keys and a short load path to the table, this board was much more rigid than the last and has been my daily driver ever since!

Test fitting the keycaps and stabilizers. I hadn’t made a PCB before, but I managed to get it right on the first try!

Finished assembly.

This project is still in process, and the next iteration of keyboard is pending. The CAD has been finished as of 7/25/2023, and now I need to get some material for prototyping.

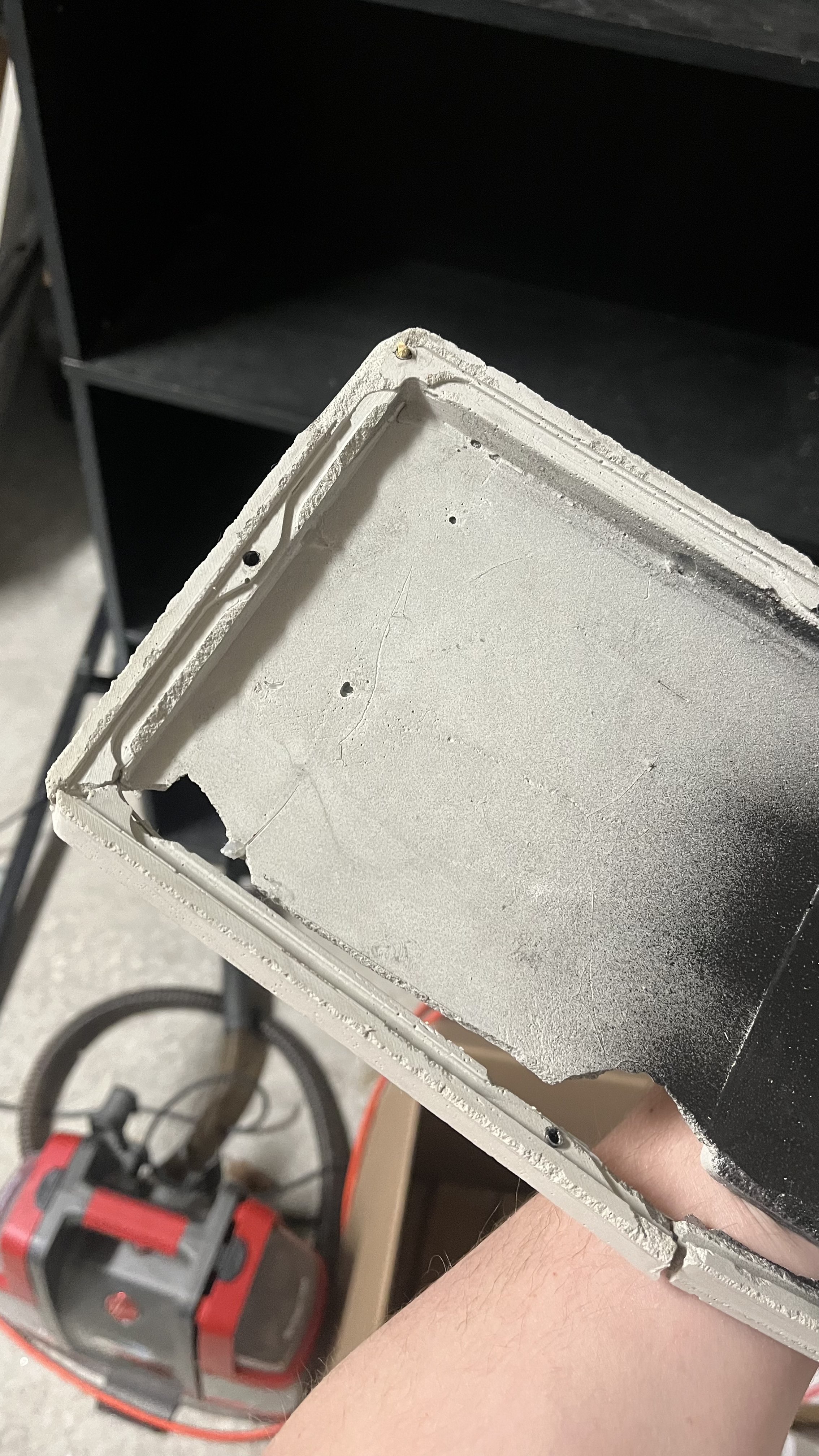

Update as of 2/21/2024 - The keyboard has been finished! I had some difficulties molding the base of the board out of concrete. Who would have thought that it would be tough to mold intricate details in concrete? Anyways, its done, and I think I am finished with keyboard for a while. I am going to include some pictures of the final product and go do something else now.

And here it is!

Here is a notable failure of the concrete base. The screw holes and gasket channels molded suprisingly well, but the base surface was too thin. I ended up replacing the base with an aluminumn plate, which probably helped its strength as well.