In solids and materials lab, my team designed a filter cartridge for Covid-19 masks.

The premise of this project was to support doctors in developing nations (and developed ones) with the mask shortage. The mask we created must be cheep and easy to manufacture, ergonomic, withstand specifed cleaning processes, and be reasonably airtight.

Thermoformed shell without the silicone face-seal or filter cartridge assembled.

Our professor supplied us with a thermoformed shell that he created. Additionally, he and a few other professors had designed a silicon mold that could produce a comfortable and airtight seal around the face.

Original design. The variation of the thermoformed shell's surface made it diffacult to produce a good seal.

He had originally tried to mount a cartridge on the mask with 3D printed threads and a gasket but found that it was difficult to print and formed a poor seal. Our job was to find another way to mount a cartridge off the thermoformed surface.

Explosion view of the cad models. The grey parts are 3D printed and the purple one is the thermoformed shell.

This was achieved with magnets imbedded in both parts. The attraction between the inner and outer 3D printed parts was more than strong enough to hold the mask together when not in use, and when in use, the mounting points of the straps helped to further secure everything. Magnets were chosen because the allowed the mask to be taken apart easily for cleaning and minimized the amount of critical seals.

Exploded cross section of the overall assembly. The 3D printed parts are grey, the thermoformed shell is purple, and the filter membrane is green.

The original design had critical seals at the interface between the 3D printer part and the thermoformed cartridge in addition to another one at the mask’s filter membrane. This design combined those seals by putting the filter between the outer 3D printed part and the thermoformed shell. When worn, the 3D printed part was pushed against the filter membrane which formed a seal against the shell. The masks’ mounting points were carefully considered so that the force from the straps supplements the filter’s seal in addition to creating the seal between the silicon cushion and the users face.

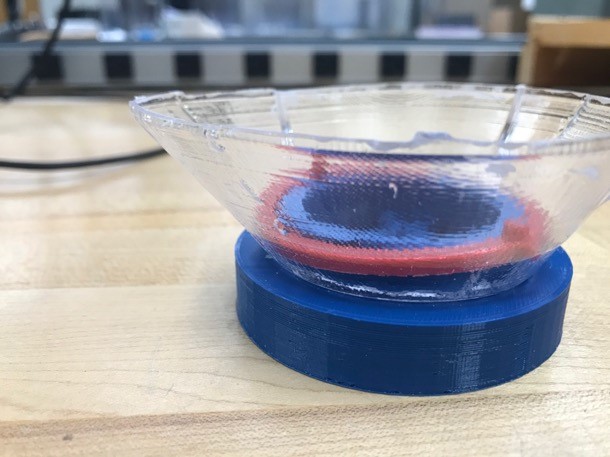

The first prototype, fresh off the printer.

The first prototype printed easily and highlighted a few small improvements. The thermoformed shell had changed from its cad model and the fit needed to be adjusted. Additionally, the two strap-mounts needed to become four.

This class is ongoing, so unfortunately the mask isn't completed yet. As writing this, the part files are submitted and will be tested as soon as they print.